Development Design

Fuweiwang carries out all-round work on precision metal parts from specification inspection to design according to customer's needs. We have design experience and professional knowledge in the fields of electrical engineering, optics, automobile, medical care, security and aviation, and can actively respond to customers' difficult requirements.

Mold Design

Mold design is at the core of realizing your required functionality and quality.Fuweiwang metal offers “value added design.” This means that we add a value to your requests employing a value analysis.

To address extended the lifespan of molds, We apply our wide-ranging know-how in using ultra-hard materials, surface conditioning, and switching loss reduction using a cassette method.

We use our own check list in our detailed meeting with you to make sure that every item in your request is reflected. Our cutting-edge 3D CAD system and years of accumulated know-how can generate processing data in a short time.

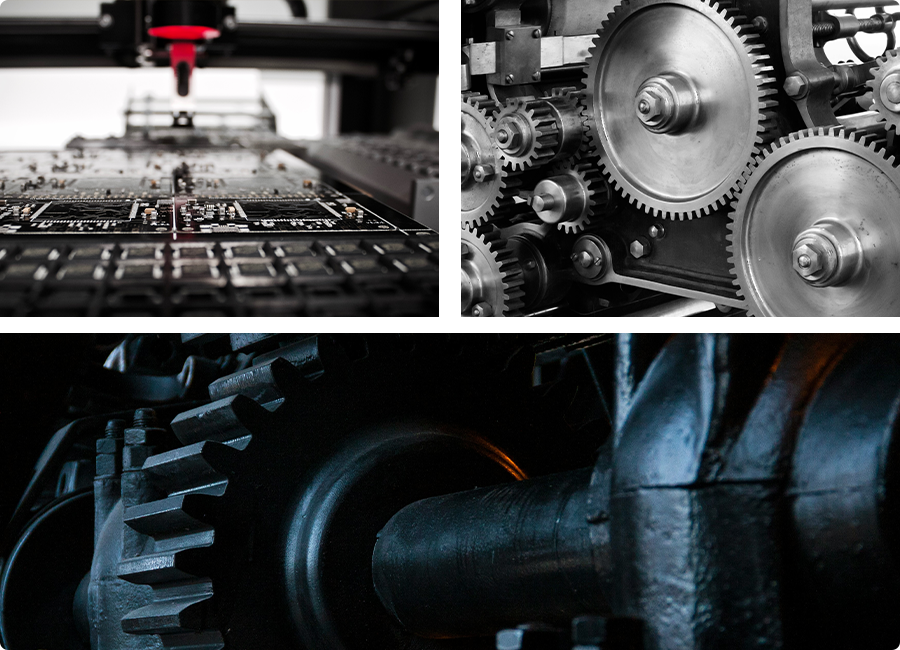

Ultra-Precision Machining

We have built in-house facilities and peripheral control technologies to make molds with a center deviation of 1 micrometer or less to realize the ultimate precision.In particular,

Molding Technology

The technology we have can completely transfer the curved surface generated in the design stage to the mold/product during the metal forming process, thus achieving stable reproduction in the mass production process. By building independent technology and infrastructure, we ensure the stable performance of products in the early/middle/late stages of production.

Welding Technique

We adopt high-efficiency precision welding technology to ensure the metal structure and mechanical properties of the weld. Especially, the welding of active metals, refractory metals and workpieces with high quality requirements is easy to realize mechanization, automation, stable quality, low cost and high efficiency, and the best welding effect is obtained.

Polishing Technology

We adopt a new type of environmental protection polishing technology, and the oxide particle size of the polishing solution is small and the hardness is strong, so there is no scratch when polishing, and the polishing effect is good.

Packaging Technique

We employ in-house assembly equipment and jigs, as well as efficient assemble procedures to assemble precision component units consistently. Improved precision of assembly equipment enable us to support the high precision of unit products.

Measurement evaluation and analysis

High-quality products require precise and accurate measurements and measurement technologies. Design tolerances with accuracy measured in micrometers are already applied in many industries, And become a reality as an industry quality standard ,these requirements are becoming more stringent year after year.

For high-precision and complex shapes,which requires measurement, analysis and evaluation technologies using a 3D measuring instrument.Using image processing, magnetic particle inspection is used on the surface of metal parts,X-ray fluoroscopy testing, ultrasonic testing, eddy current testing is used to perform non-destructive testing of the internal structure of metal parts etc.

Fuweiwang metal is always working on improving measurement and evaluation technologies to support your various requirements.

Value-added services

Our services are not limited to ensuring the product quality during the start-up and project phase but rather focus on achieving the perfect result together with our customers. This is why we endeavor to always work in a solution and customer oriented manner. Thanks to our design & construction, our project management and our purchase policy, we are able to implement our customers’ wishes in an efficient and fast way. We will gladly advise you on optimization and cost potential issues as well as on further efficiency topics and material selection. We also take care of customized packaging.